COVID Safety

COVID-19 SAFETY

TAKE A LOOK AT HOW OUR TEAM IS HANDLING THE GLOBAL PANDEMIC AND NEW HEALTH GUIDELINES

In-Person Work Day Acknowledgment Form

The form pertains to the Waialua Robotics Program, the Waialua Robotics STEM Learning Center, and the 21st CCLC Program.

THE FORM ITSELF CAN BE FOUND HERE.

As mentioned above, at the beginning of the school year, all participating students for the upcoming season along with their parent or guardian must complete an in-person acknowledgment form in order to partake in any workdays. This form covers safety procedures in light of the ongoing pandemic. As a safety policies acknowledgment form, it covers cleaning & sanitizing, physical distancing, health & safety, and facility safety. Students must read over the form with their parent/guardian in which they must sign after. All forms are turned into the team lead mentor, Glenn Lee. With this form, not only is it a documented agreement between students and how they must act in the facilities, but it’s also a form of consent from parents, allowing their children to be in our facilities.

COVID Kit

And while Team 359 has taken the opportunity to reach out to the community and give back to our first responders, we’ve also taken the initiative to delve deeper. That comes in the form of COVID-19 relief kits. As a part of having students be able to work in the facilities again, together with our school’s After School All-Stars (ASAS) Program, we’ve created a relief kit that can be found in respective facilities. This kit comprises of spare disposable face masks, face shields manufactured in our in-house facilities, hand sanitizers, a temperature gun, and a log journal to go with it. The temperature gun and daily log allow ASAS and Waialua Robotics to conduct daily temperature checks to monitor everyone’s wellbeing.

Students are recommended not to attend workdays if they’re experiencing any signs of fever, fatigue, headache, nausea, etc. In the event a student stays home, they are responsible for informing their subdivisions mentor(s).

Due to COVID-19 circumstances, everyone has had to adapt to new conditions in order to be a properly functioning society again. As a team, we have taken every precaution to ensure the safety of all team members and mentors, so that we are able to return back to our facilities. In these tough times, our team has also taken the opportunity to help out our community and our local front line workers. This includes lending our resources to other organizations and even creating our own special products. These products include face masks, face shields, desk shields, and many more.

If you would like to know more about purchasing these items, feel free to visit our “Special Projects” section within the website.

Personal Protection Equipment (PPE) Projects

In these tough times, our team has also taken the opportunity to help out our community and give thanks to our local front line workers. Many of the projects we’ve created were thanks to the resources our facilities have provided including one of our mentors, Mr. Sean Lunasco, for spearheading many of them. This includes lending our resources and in-house machinery to other organizations and even creating our own special projects. To get a closer look at all the special projects our team has created, please visit the “Special Projects” tab. There you can find more information about each project.

Contact us if you are interested in ordering or if you have any additional questions about these projects.

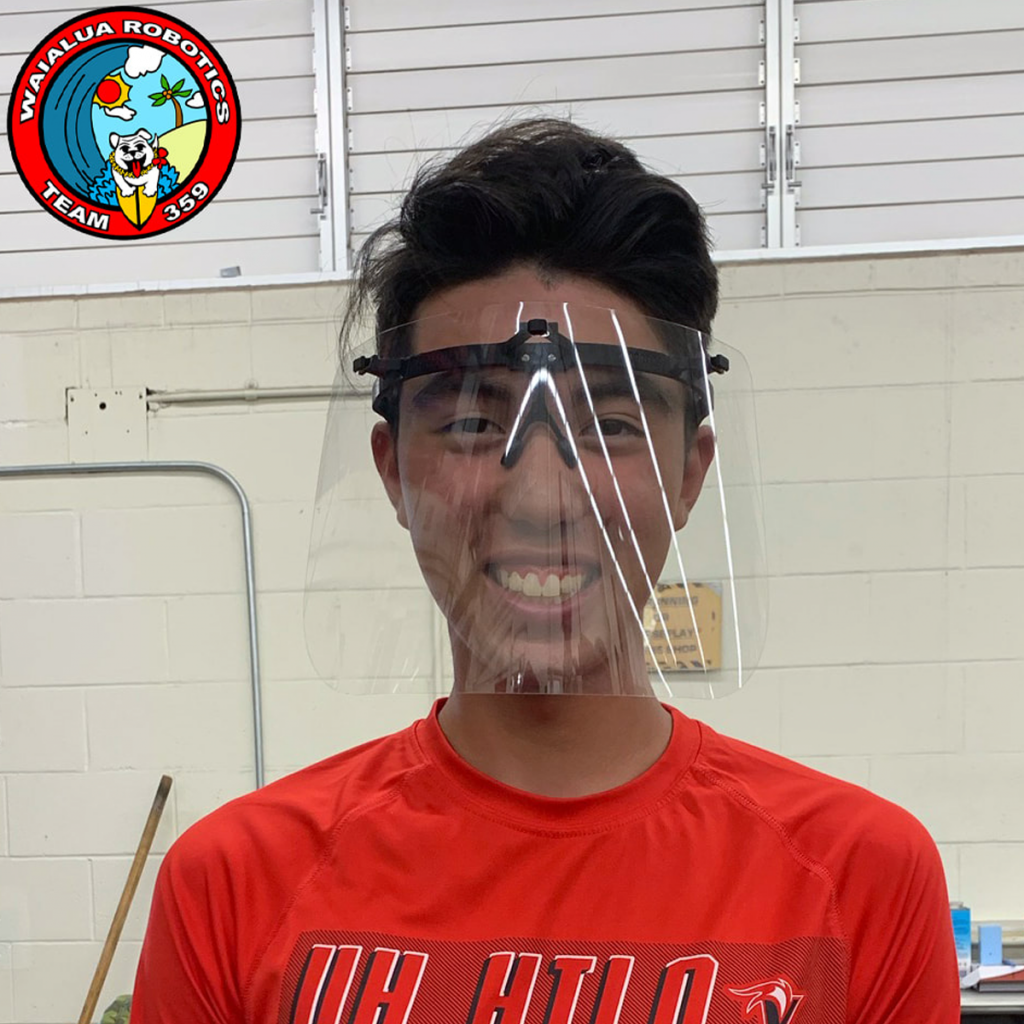

PPE Face Shield

By using our Master 3D Gage Portable CMM, our laser engraver, and a 3D printer, we were able to construct personal protective face shields. What makes these so unique from the rest is that when designing them, our team wanted to create a comfortable frame that wasn’t uncomfortable. To do this, the frame was designed to replicate the fittings and sizing of Oakley RadorLock glasses which our team particularly knows well. Because of this small detail, our face shields are a tad bit more comfortable than the typical one. Since the initial launch, we have made more than 2,000 face shields.

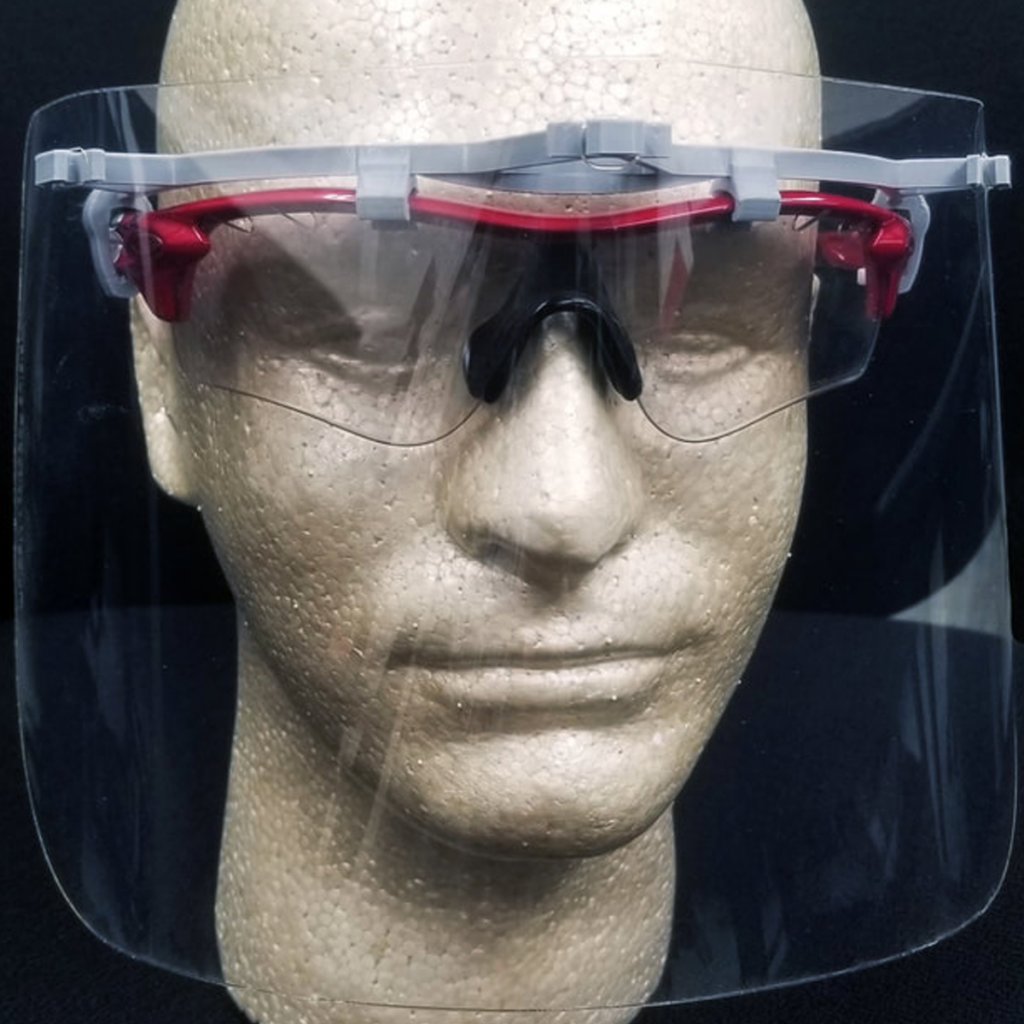

PPE Safety Eyewear Clip-on Shield

As an alternative to our face shields, the team also custom-created face shield clip-on, designed to fit Oakley RadorLock glasses, a popular model within our team. Similar to the regular face shields, we utilized our in-house Master 3D Gage Portable CMM, our Laser Engraver & one of our 3D-Printers. These convenient clip-ons allow for quick removal of the shield also allowing you to turn your favorite pair of safety glasses into a face shield.

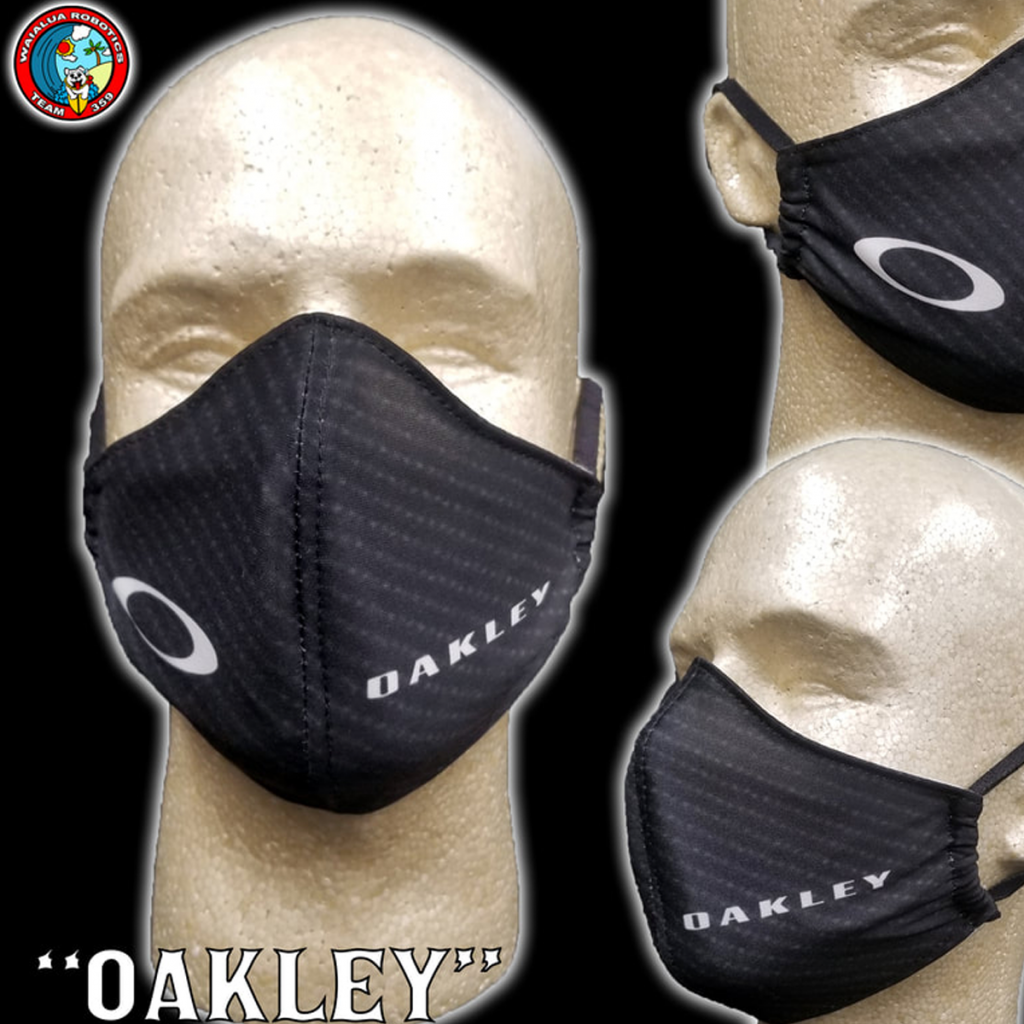

Custom Printed Face Masks

The team utilizes our Laser Engraver, Wide Format Sublimation Printer, and Heat Press, to create custom printed face masks. The face masks themselves are made with polyester & cotton fabric and soft elastic bands. The masks aren’t only comfortable but also provide a more protective fit than a typical homemade mask. We’ve since been able to create custom masks for our own team, Maui Sporting Goods, our Oakley sponsor representative, etc.

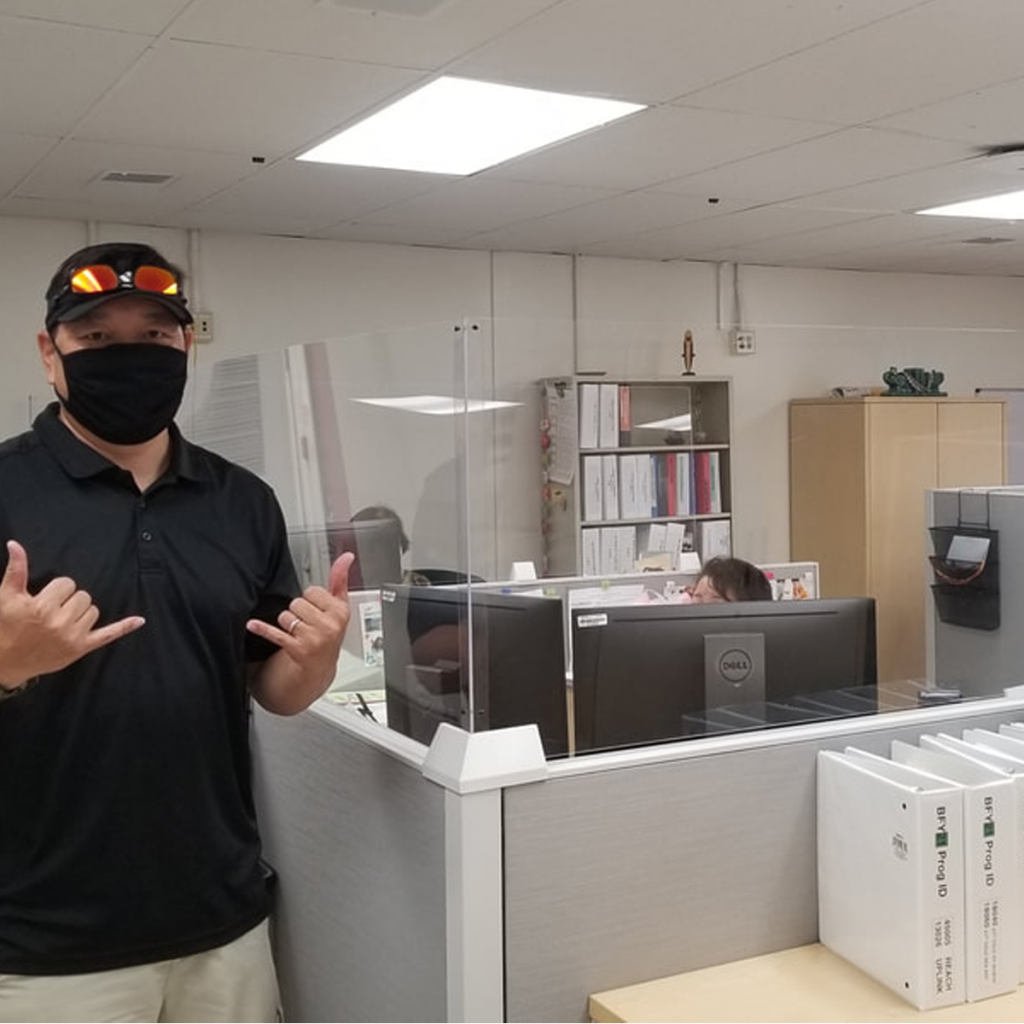

COVID-19 Spray Shield

In August, the Department of Education’s Community Engagement Office reached out to the team to construct splash guards around their office cubicles. With the given measurements, we used our in-house laser engraver and tap machine to cut out type G Acrylic along with polycarbonate brackets. We then directly mounted the cutouts onto the cubicles with screws and washers.

Portable PPE Table Top Spray Shield

Alternative: “L-SHAPE” Type

The Honolulu City Clerks Office reached out to the team back in September to enlist our services to construct a tabletop spray shield that could be put up, taken down, and rearranged with convenience. Using our in-house resources, we were able to make a portable tabletop spray shield back in September. We used our 3D printers to print out the corner pieces and connectors. By using our band saw, cordless drill, and a bench drill deburrer, we were able to put together the rest of the spray shield using specific materials.

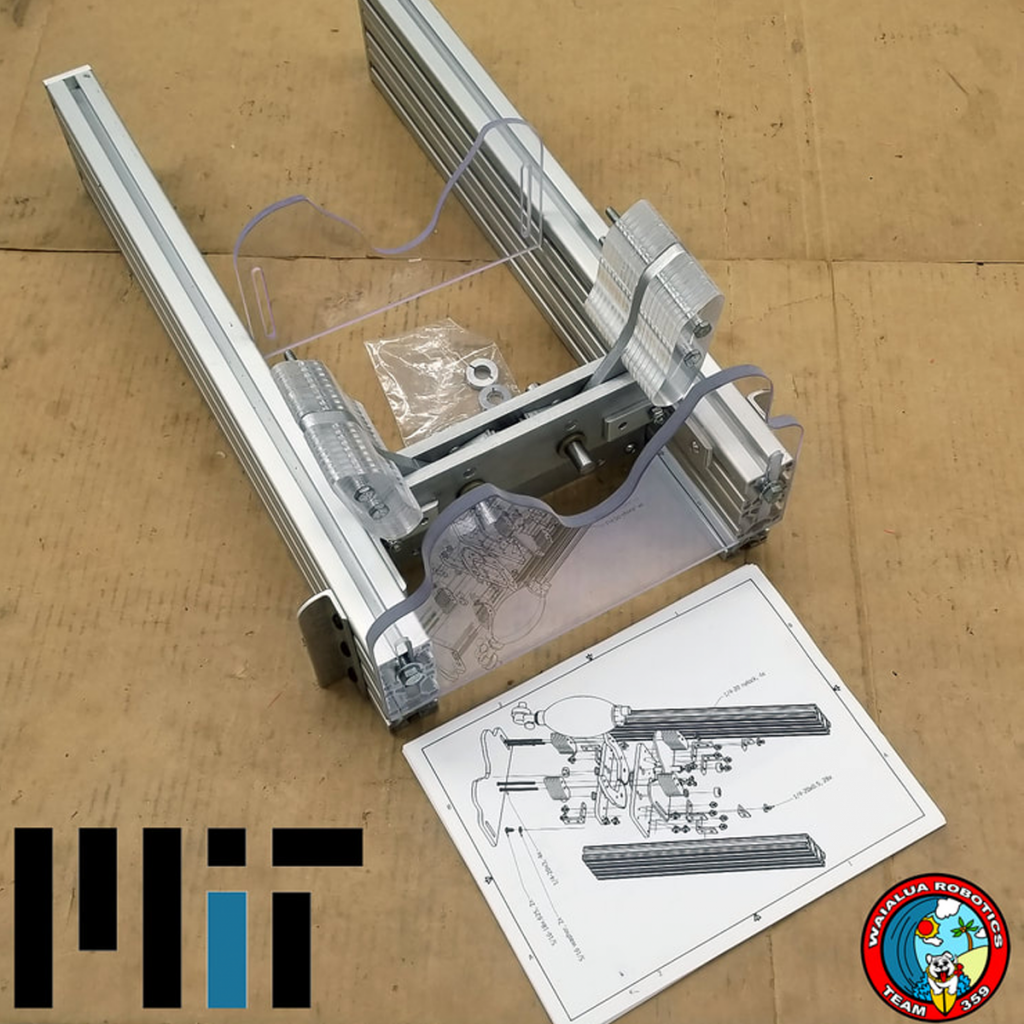

Emergency Ventilator Pre-Production Prototype

Using aluminum, acrylic, polycarbonate, and extruded aluminum T-slot framing, the team constructed an emergency ventilator pre-production prototype. This MIT Emergency Ventilator was designed and engineered by MIT. However, Waialua Robotics was contacted by a local doctor in Hawaii to build the prototype in the event of an emergency shortage of Ventilators here in the islands due to COVID-19. Waialua Robotics was able to produce a prototype according to the plans.

No Draft Speak Thru Cover

The Honolulu City Clerks Office reached out to the team in June to construct a speak-thru divider that would separate employees behind the counter to the general public. Utilizing our laser engraver and tap machine we cut out Type G acrylic pieces which we later assembled in their office. What makes our speak-thru cover so unique is that its draft preventing and it allows clear communication.

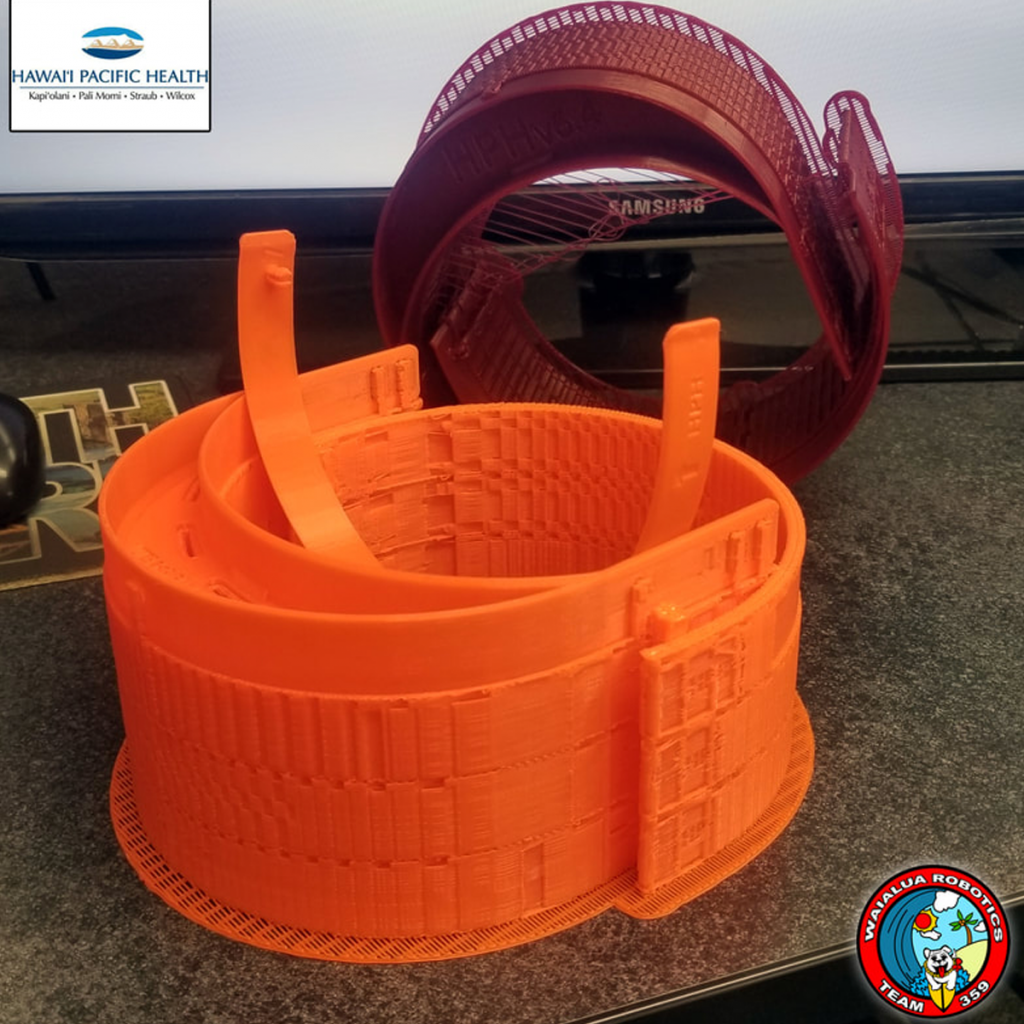

Hawaii Pacific Health PPE Face Shield Frames

In April the team assisted Hawaii Pacific Health (HPH) in making PPE face shield frames. With our Afinia 3D printer, we printed a model frame through Autodesk Inventor using premium PLA 3D printing line. The team assisted in printing these to help the demand for supplies during the first initial outbreak of COVID-19 on Oahu.